- Home

- Company▼

- Quality▼

- Diamond tools for marble▼

- Diamond tools for granite and natural quartz▼

- Diamond cutting disc for granite and natural quartz

- Diamond wire for cutting granite and natural quartz

- CNC diamond tools for processing granite and natural quartz

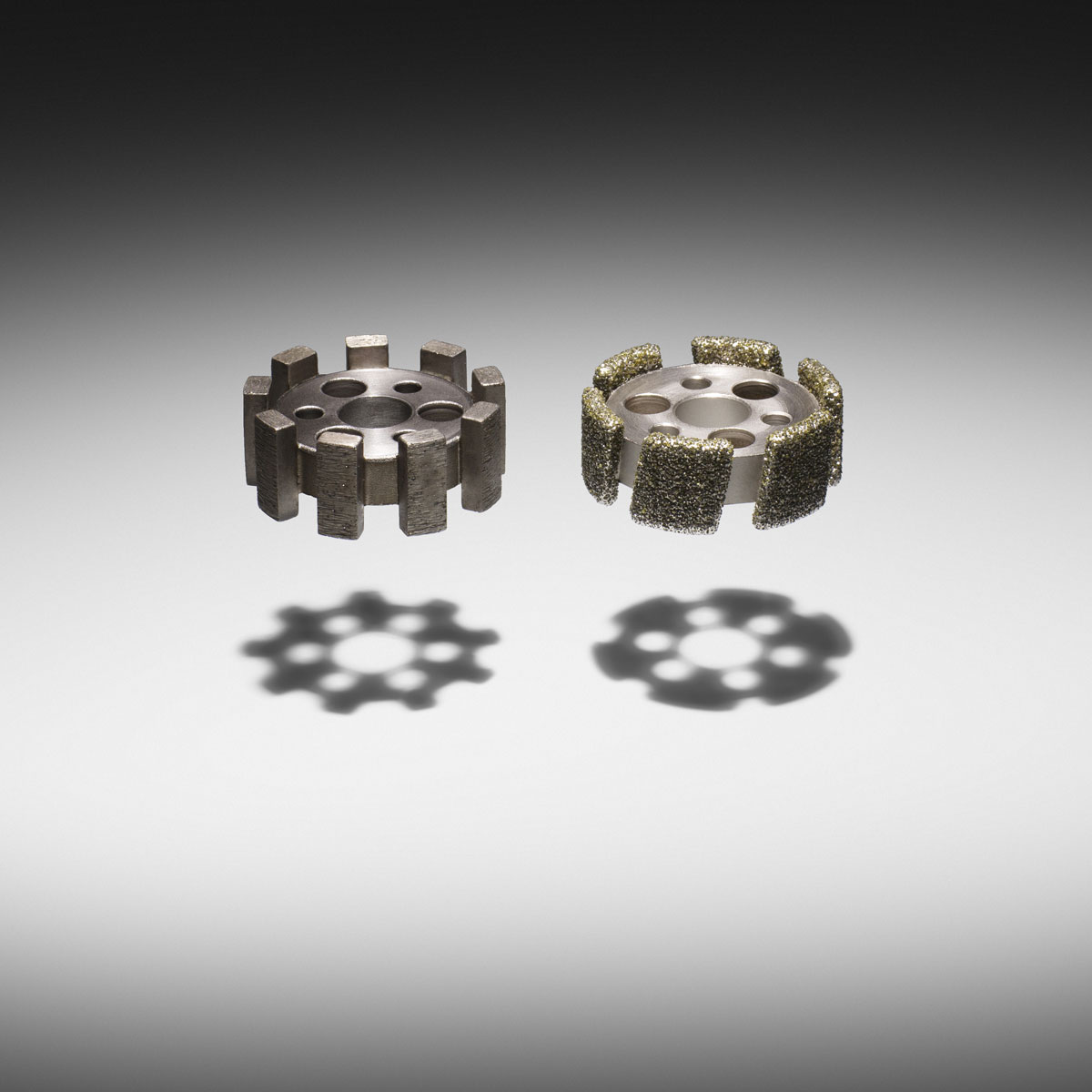

- Diamond tools for calibrating granite and natural quartz

- Diamond tools for polishing granite and natural quartz

- Diamond Segments

- Diamond beads for stone cutting

- Diamond tools for ceramics▼

- Diamond tools for agglomerate▼

- News

- Contacts

▼

▼